Fe 550:

This widely accepted grade from Kamachi is manufactured with minimum 5 % higher strength than BIS standards and can save up to 30 % when compared to ordinary TMT bars. Excellent elongation, bend and re-bend properties and superior weld ability makes Kamachi TMT the preferred choice of engineers and bar benders alike.

Chemical Properties

Carbon % max 0.25

Sulphur % max 0.050

Phosphorus % max 0.050

Mechanical Properties

Yield stress 580

Ultimate Tensile Stress 680

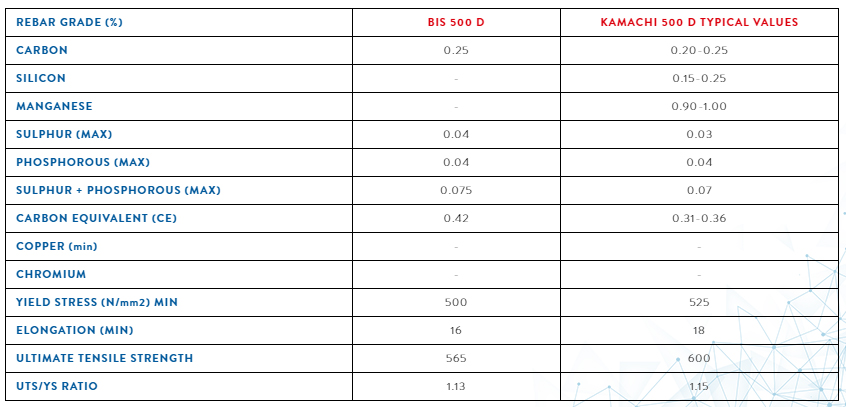

Fe 500 D:

Also known as the Earthquake Specialist, the 'D' denotes the extra ductility of the rebar. The best qualities blooms ensure extremely low levels of Sulphur and Phosphorus impurities. The lesser these elements, the greater the ductility and ability to withstand the tremendous shock load produced during earthquakes.

Kamachi Fe500D bars not only offers better value and durability than presumed leading brands, it is also trusted by India's leading industrial houses.

Chemical Properties

Carbon % max 0.20

Sulphur % max 0.035

Phosphorus % max 0.035

Mechanical Properties

Yield stress 580 N/mm2

Ultimate Tensile Stress 600 N/mm2

HCRM:

Kamachi HCRM (High Corrosion Resistant Material) is an Fe500 steel that has the added elements of Chrome (Cr), Nickel (Ni) and Copper (Cu); that are present uniformly from core to surface, fight corrosion from sea water, acidity and salinity and maintain structural strength.

The price difference compared to normal Fe500 is negated and the differential cost converts to savings against foundation re-strengthening and annual maintenance. The presence of higher corrosion resistant elements and availability at lower rates than market leading brands and main steel plants is a positive point in addition to increased structure life.

Chemical Properties

Chromium 0.40-0.50

Copper 0.20-0.30

Total Corrosion Resistant Elements 0.45% min

Mechanical Properties

Yield stress 525

Ultimate Tensile Stress 600

Fe 600:

Kamachi Fe600 is the steel for new age high-rise constructions. The steel strength of 600 MPa offers a 20% increase in load bearing capacity leading to atleast 4% lower steel consumption and immense savings; value for money. The extremely low sulphur and phosphorous content gives the steel increased ductility to withstand wind loads and jerk loads during earthquakes. Being pioneers to launch this special quality steel in the market, it is priced equivalent to HCR bars, providing maximum benefits at minimum costs.

Chemical Properties

Carbon % max 0.25

Sulphur % max 0.035

Phosphorus % max 0.040

Mechanical Properties

Yield stress 630

Ultimate Tensile Stress 670

Readymade Money Savers

Readymade Steel

Quality, Reliability, Speed & Effciency

The application of technology to any process achieves accurate control on all required parameters. Processing steel at the job site is hard, drganised endless productive. The emerging trend is to shift steel processing to service centres, which offer a controlled environment. Readymade steel processed at our factory saves money through reduction of time and manpower. Readymade steel accelerates construction time and helps construction firms tide over scarcity of skilled labour, stringent timelines and quality standards while adhering to health and safety guidelines.

Benefits of Kamachi Special Length Steel :

- Special length Kamachi Steel is available for upto 34 meters

- Accurate measurements like 30.6 meters cutting is also available

- Success of Special Length Steel is already proven in bridges and roads operations

- Consumers benefit lower costs as on the fly production cut, leads to minimum losses during production

- Special vehicles are made available by Kamachi for delivery to required site

- Double bending of 40 mm Kamachi Special Length Steel is also available

Advantages of Readymade Steel

Time Saving

Elimination if onsite labour with delivery of customised readymade steel coordinated to construction requirements saves processing time.

Zero Wastage

There is no wastage of steel as there is no onsite processing. The customer only pays of the actual steel used, blueprint weight, saving on waste, processing and freight.

Avoid Theft

Material is ordered and delivered as per need eliminating the need for storage. There is no loss due to theft of stored steel.

Robot Technology

Advanced robotic technology is used in the processing of steel. This helps achieve accurate control over all required parameters for superior quality.

Precision

The steel bars are bent using the latest technology in a controlled factory environment. This achieve absolute accuracy.

Any Shape / Any Size

Mechanized processing enables us to customize shapes and designs as per requirement. This provides absolute freedom of design.

HERE IS WHY WE ARE UNIQUE

Vision

To set new benchmarks of being an organisation of processes and people to ultimately reach the most honorable and admirable stature among competitiors and business organisations.

Mission

OUR CLIENTELE

Testimonials

5 months since doing business with KamachiTMTBars.

Quality is good.

2 years since doing business with KamachiTMTBars.

High in demand. Excellent quality.

1 year since doing business with KamachiTMTBars.

Rise in Profits.

An increase in demand in Kovilpatti.

During these 3 months of being partnered with 3 months since doing business with KamachiTMTBars, business has grown since due to quality and affordable prices.

Great quality and customer service since 6 months with on-time delivery to customers.

-

2000

Inception idea for setting up the largest integrated steel plant in TN dedicated to TMT Bars

-

2013

UNIQUE FEAT

December of 2013 saw Kamachi reach the unique feat to reach 1 Lakh MT sales

-

2016

POWER BRAND

We join the Prestigious TATA group, Chennai Metro and Military engineer Services client list

-

1978

From local trading to setting up international trading arms, the group commenced its own

-

2011

We complete the mega plant and roll out 1st TMT Bars.

-

2015

UNIQUE FEAT

In 2015 Kamachi TMT Brand was awarded with 3 prestigious title

-

2017

Fe 600 become part of Kamachi’s quality line up. We introduce MS Rounds suitable for highways ‘Dowell’ Bars. Only prime manufacturer to do so.